Views: 8 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

You see big changes in mining because underground mining vehicles use advanced autonomous technologies. These vehicles help keep you safe. They help you work faster and save money. You also help the environment. Automated systems can lower emissions and energy use by half. This has happened at Alamos Gold and Boliden’s mines. Today, you can use smart trucks, drilling rigs, and drones. They move materials, watch for safety, and check the environment. These changes make mining safer and better for everyone.

Autonomous underground mining vehicles make work safer. They keep people away from dangerous jobs. This means there are fewer accidents and injuries. These vehicles can work all day and night. They do not need to stop for breaks. This helps mines get more work done faster. Automation saves a lot of money. Companies do not need as many workers. They also spend less on fixing machines. This lets companies use their money better. These vehicles are better for the environment. They use less energy and make less pollution. This helps mining companies reach their green goals. The vehicles give real-time data and help with predictive maintenance. This makes work run smoother. It also helps people make better choices and have less downtime.

Working in underground mines can be dangerous. There are heavy machines and falling rocks. The air can be bad too. Autonomous underground mining vehicles help you stay safe. These vehicles use GPS and real-time data to do jobs. They drill, haul, and survey without needing people close by. You do not have to stand near risky equipment. Driverless trucks and loaders move things without people inside. You can watch machines from far away in remote centers. Drones check sites so you do not walk in unsafe tunnels.

Tip: Using robotic machinery helps stop mistakes and accidents at work.

Here is a table that shows how different technologies make mining safer:

Technology Type | Impact on Safety |

|---|---|

Autonomous Drilling Systems | Work with little help from people, so there are fewer accidents. |

Robotic Machinery | Do hard jobs by themselves, which lowers mistakes and keeps people safe. |

Tele-remote Control Systems | Let people control machines from far away, so they do not get hurt in dangerous places. |

AI Integration | Finds problems with equipment early and makes work safer for everyone. |

Using autonomous underground mining vehicles helps stop accidents. These vehicles do not get tired like people do. This means fewer mistakes happen. Many mining companies have fewer accidents after using automation. Experts think accident rates will drop by 30% by 2025. Keeping people out of dangerous places helps workers stay safe.

Machines do risky jobs, so people get hurt less.

Watching from far away keeps you out of danger.

Drones and sensors find problems before accidents happen.

A new study used light-band-guided driving for transport vehicles. This way, safety risks for workers went down a lot during mining. You can trust technology to help keep you safe underground.

Autonomous technologies let mining work all day and night. Regular vehicles need breaks, but these do not. You finish more work in less time. GPS and AI help vehicles move safely and carry heavy loads. They work well even in hard underground places. You do not stop for safety checks or because workers get tired. Here are some ways these vehicles help you work nonstop:

Machines keep working, so production does not stop.

No drivers are needed in risky spots, which keeps things safe.

Smart sensors help vehicles avoid crashes and slowdowns.

Underground mining vehicles can get minerals very accurately. They use lidar, infrared sensors, and AI to find the best way. These vehicles avoid mistakes and pick the right path. They change drilling and blasting by themselves if things change. Real-time data lets them check their work and fix problems fast.

Evidence Description | Explanation |

|---|---|

Precision navigation | Vehicles use sensors and AI to move and extract with high accuracy. |

Smarter decision-making | They change drilling and blasting for the best results. |

Continuous data integration | They watch and improve extraction as they go. |

Autonomous trucks help mining run better and smoother. For example, Rio Tinto used these trucks to move 200 million metric tons in six years. By 2016, all their iron ore moved with driverless trucks. The Syama Gold Mine was the first fully autonomous underground mine in 2019. It used automated drilling, loading, and hauling. Volvo’s autonomous truck in the Kristineberg Mine travels 7 kilometers underground. It uses sensors to dodge obstacles and keep transport safe.

Autonomous trucks help move materials faster and safer. This makes mining more efficient.

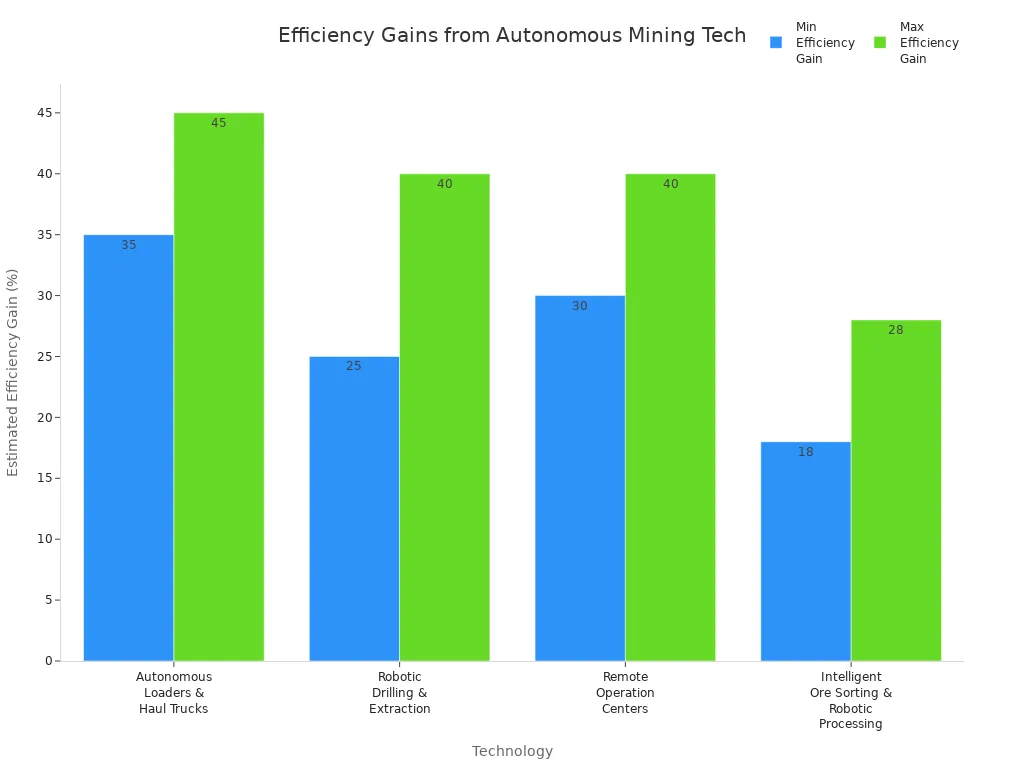

Technology | Estimated Efficiency Gain |

|---|---|

Autonomous Loaders & Haul Trucks | 35–45% |

Robotic Drilling & Extraction | 25–40% |

Remote Operation Centers | 30–40% |

Intelligent Ore Sorting & Robotic Processing | 18–28% |

Mining companies can save a lot of money with autonomous equipment. When machines drive themselves, fewer workers are needed underground. This means companies spend less on pay and training. Fewer people in dangerous places also keeps everyone safer. Here is a table that shows how these changes help you:

Evidence Type | Description |

|---|---|

Labor Cost Reduction | Autonomous vehicles eliminate the need for human drivers, directly reducing labor costs. |

Safety Enhancement | By reducing human exposure to dangerous areas, these vehicles enhance overall safety in operations. |

Automated systems improve efficiency, leading to higher production volumes and reduced idle time. | |

Productivity Increase | Mining automation can boost productivity by 5-10%, equating to the output of a new mine. |

Using underground mining vehicles that drive themselves leads to fewer accidents. With fewer accidents, companies pay less for medical bills and repairs. Less time is lost when workers do not get hurt. This helps companies save money and work better. Look at this table to see how fewer accidents help your business:

Evidence | Explanation |

|---|---|

Fewer accidents lead to reduced costs associated with medical expenses, legal fees, and lost productivity. | This indicates a direct financial benefit from fewer accidents, which can significantly improve the bottom line for mining companies. |

Enhanced operational efficiency and safety from autonomous vehicles can lead to increased profitability. | This suggests that not only are costs reduced, but revenues may also increase due to improved operations. |

Customers using our autonomous haulage system see big cost savings. Komatsu’s AHS customers saved up to $600 million since moving 2 billion tons with these trucks. In 2020, they saved between $0.50 and $0.62 for every ton moved.

Autonomous trucks help save money on repairs and last longer. These trucks have over 200 sensors to check things like engine heat and tire wear. Machine-learning systems find problems early, so you can fix them before they get worse. This kind of maintenance makes repairs 30% more efficient. You do not have to stop work as much, and you avoid big breakdowns.

Autonomous mining truck designs lower engine stress and reduce wear.

Traditional trucks break down more often and cost more to fix.

You spend less on parts and repairs, which helps your mining industry stay strong.

Using autonomous equipment, like drill rigs and haul trucks, is changing mining.

Autonomous equipment uses less fuel.

It cuts down on waiting time.

It lowers mistakes, which saves a lot of money.

When you use autonomous underground mining vehicles, you help the mining industry get closer to net-zero goals. Electric and battery-powered equipment makes much less pollution than diesel machines. This helps the air underground get cleaner. It also makes mining safer and easier. You do not need as many big ventilation systems. This saves energy and money. Here are some ways automation helps the environment:

Automation cuts down on pollution and saves energy. Boliden’s mines in Sweden saved half their energy each year with automated ventilation.

Battery-electric trolley truck systems give new ideas to lower harm to the environment.

Automated equipment can cut global warming effects by 17.9 kg of CO₂ for each tonne of ore.

You help lower project ghg emissions and cut down on operational emissions.

Autonomous vehicles make mining use less energy. These machines have smart sensors and AI. They only work when needed. This stops waste and keeps work steady. The table below shows how you save resources:

Benefit | Percentage Reduction |

|---|---|

Fuel costs | 30-40% |

Maintenance expenses | 25% |

Insurance premiums | 20% |

Operator training costs | 15% |

Direct emissions (when renewable) | 80% |

Ventilation requirements | 60-70% |

You do not need to stop for shift changes or breaks. Machines follow set rules and keep working without slowing down. You get better safety and fewer problems, which also saves money.

Using autonomous underground mining vehicles helps protect the environment. Mining now tries to use less land and new underground methods. You help switch to electric fleets and use better processing technology. These changes help you work better and lower harm to nature. Drones and robots work in dangerous places, so people stay safe. 3D laser scanning and LiDAR give real-time data to find dangers and work better. By choosing these ways, you help reach net-zero goals.

You help make mining cleaner and move closer to net-zero.

You can make smarter choices in mining with real-time data. These systems use sensors on autonomous trucks and other machines. You see what is happening underground right away. Remote monitoring lets you check machine health and safety from a control room. Machines talk to each other and share updates fast. The Internet of Things links equipment and sends data for quick checks. This helps you see what is going on and use resources better.

Benefit | Description |

|---|---|

Continuous Monitoring | Automated systems collect data in real time for ongoing oversight. |

Predictive Maintenance | Data analytics help predict equipment failures before they happen. |

Resource Management | Real-time insights help you use resources better in mining operations. |

You use smart fleet tools to follow mining plans and keep things running well. AI helps you pick the best routes and speeds for moving stuff.

You keep your autonomous mining truck and other machines working longer with predictive maintenance. Real-time data tells you when parts need fixing before they break. You avoid costly shutdowns and keep production steady. Finding problems early means you spend less on repairs and parts. You also keep workers safer by stopping failures before they happen.

Less downtime saves money and keeps mining on track.

Finding electrical problems early helps machines last longer.

Fixing only what is needed lowers costs and labor.

Fewer breakdowns make work safer for everyone.

One day without surprise shutdowns can pay for your whole predictive maintenance plan.

You face some problems when you add autonomous technologies to your mine. Machines must work well in tough underground places. Sometimes, sensors spot things that are not really there or lose signals. You need to plan well to fit new systems with old ones. Buying and upgrading equipment can be expensive for small companies. You must follow strict safety and environmental rules. Training your team is important. Workers need to learn new skills and use tools like augmented reality to work safely with machines.

Switching to fully autonomous mining means you must build a strong safety culture and train your people well.

Challenge Type | Description |

|---|---|

Reliability | Machines must work in harsh conditions and avoid false alarms. |

Integration | New systems must fit with old infrastructure without causing problems. |

Cost | High costs for buying and maintaining equipment can be a barrier. |

Regulation | You must follow safety and privacy rules when using autonomous haulage system. |

You notice big changes in mining with autonomous underground mining vehicles. These machines help you stay safe and finish work faster. You spend less money and help the environment. Mining becomes easier to plan and more productive. Technology and people working together make these changes even better.

Workplaces get safer, and jobs happen on a steady schedule.

Many mines will soon use smart trucks and loaders.

Automation will do dangerous jobs, so you can do other important work.

You are helping to make mining smarter and safer for the future.

Autonomous underground mining vehicles move, drill, and haul things by themselves. They do not need a driver. These vehicles use sensors and computers to work in mines. They help keep people safe and get jobs done faster.

These machines make mining safer and more productive. They can work all day and night without stopping. They help stop accidents and keep the mine running well.

Workers are safer because they do not stand near big machines. Sensors and cameras find dangers early. People can control the vehicles from a safe spot.

Electric vehicles and smart systems help the mining industry. They lower pollution and save energy. Using less fuel means less harm to the environment.

Small mines can use some simple autonomous tools. They can start with remote monitoring or basic automation. This helps make mines safer and better without spending a lot.

Located at Laixi Economic Development Zone of Qingdao City, FAMBITION is a well known and specialised mining trackless equipment manufacturer.

Copyright © 2024 QINGDAO FAMBITION HEAVY MACHINERY CO.,LTD. All Rights Reserved. | Sitemap | Privacy Policy